Revolutionizing Sustainable Construction with GFRC As the construction industry increasingly prioritizes sustainability, innovative materials like GFRC panels are taking center…

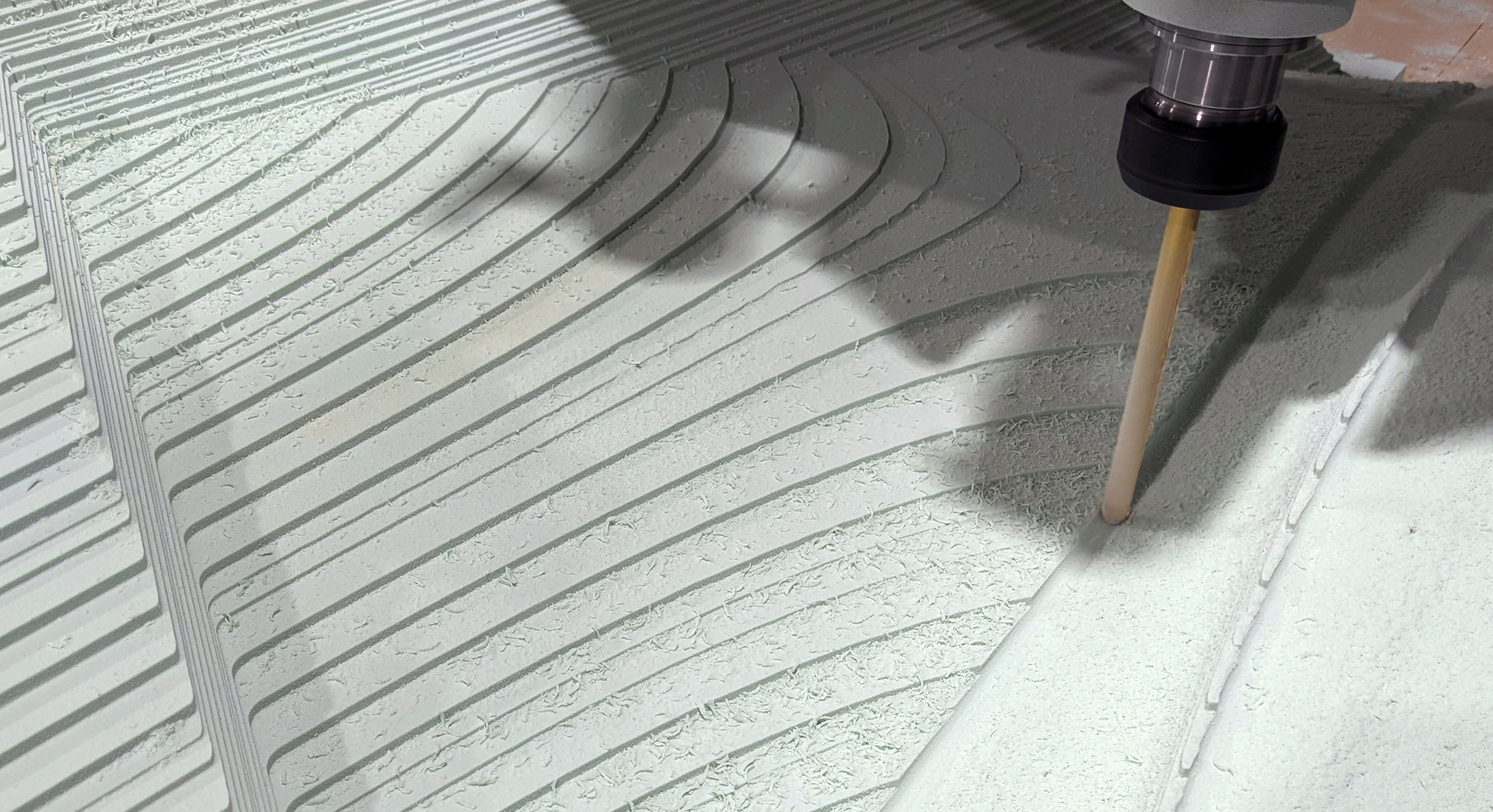

3D modeling software and CNC technology play a crucial role in the automation of precast concrete production processes. 3D modeling software is used to create detailed designs of precast concrete elements, which are then translated into machine code to be executed by CNC machines. This technology has revolutionized the production of precast concrete by allowing for precise and intricate designs to be manufactured with ease.

The application of CNC technology in the production of precast concrete elements has greatly improved production accuracy and the quality of finish. With CNC machines, precast concrete elements can be manufactured to exact specifications, ensuring consistency and precision in every piece. This technology also allows for complex designs and intricate details to be reproduced with ease, reducing the need for manual labor and potential errors.

Mold Fabrication

Mold fabrication for digital fabrication with concrete involves utilizing digital technologies such as CNC machining and 3D printing to create precise and customized molds. The process starts with designing the mold using computer-aided design (CAD) software, which is then translated into code for CNC machining or 3D printing.

CNC machines are used to carve out the mold from a solid block of material, ensuring high precision and accuracy. 3D printing, on the other hand, is used to create intricate and complex mold designs that would be difficult to achieve with traditional methods.

The benefits of using these digital technologies for mold fabrication include precise customization to meet specific design requirements and error-free fabrication, resulting in higher-quality finished products. Additionally, automation reduces manual labor, improving efficiency, and reducing costs in the mold fabrication process.

CNC Milling

CNC milling is a process that uses computer numerical control (CNC) machines to remove material from a workpiece, creating a custom-designed part or product. This process is commonly used in the manufacturing of precast concrete products.

CNC-milled templates allow for dimensionally precise precast concrete products, ensuring a high level of accuracy and uniformity in the final pieces. The use of CNC milling technology also allows for more complex and intricate designs to be achieved, as the machines can accurately replicate detailed patterns and textures onto the concrete surface.

The benefits of CNC milling for precast concrete projects include increased efficiency and consistency in production, reduced material waste, and faster turnaround times. The precision of CNC-milled templates also helps to minimize the need for manual adjustments and refinishing, resulting in a more cost-effective and reliable production process.

At Concreteworks East, our mission is to bring any designer’s creative vision to life with concrete. As the popularity of these 3-dimensional complex and organic shapes continues to grow, we continue to invest in our in-house fabrication capabilities to succeed in that mission.