In modern construction, fire safety is a critical consideration when selecting building materials, particularly for exterior wall surfaces and cladding…

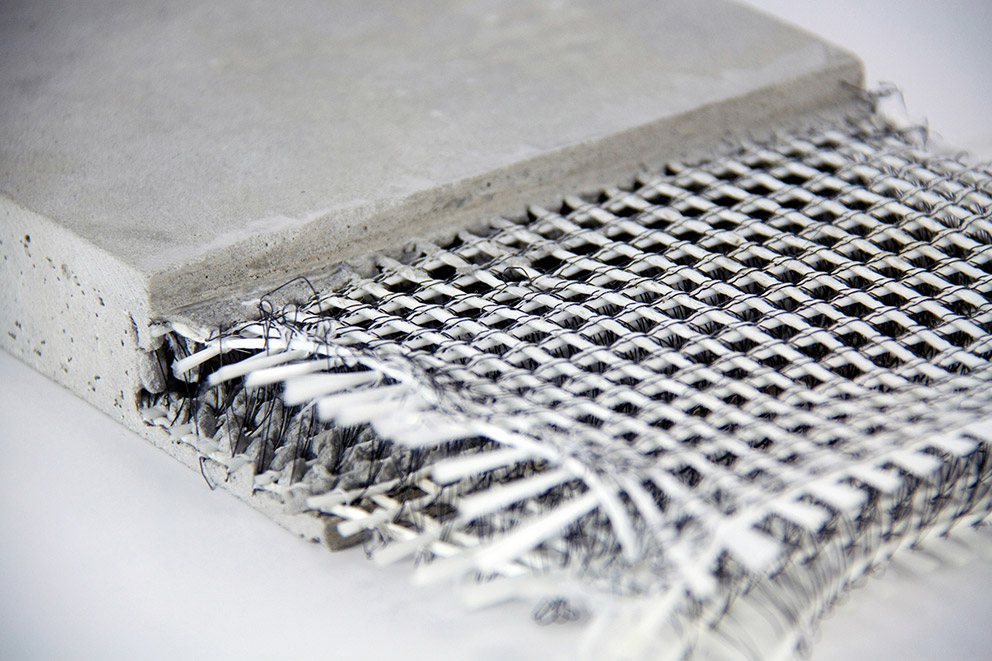

Glass Fiber Reinforced Concrete (GFRC) is a combination of Portland cement, water, acrylic co-polymer, fine aggregate, glass fiber reinforcements, and additives. The purpose of the glass fibers is to enhance the tensile and flexural strength of the concrete. This enables the concrete to be used in thin-wall casting applications. GFRC can be found in exterior cladding on new construction projects and building restoration.

The main purpose of GFRC is to replace traditional concrete. In 2015, GFRC was primarily used for architecture purposes in cladding, moldings, and landscaping. It can also be used in building and engineering foundations, floors, roofing, walls, windows, permanent framework, utilities and water management, bridges, and tunnels. Europe is the leading buyer of GFRC.

The market has been segmented by product type into three categories, Sprayed, Premix, and Hybrid. Building utilizing environmentally friendly materials and following LEED Ratings has become increasingly important. GFRC is made with recycled materials, thus it is a better material to use over traditional building materials.

The Glass Fiber Reinforced Concrete market is expected to reach a compounded annual growth rate of 9.5%. Another important facet of GFRC is its fire-retardant capabilities. This will attribute to its growth rate.

Since 1991, Concreteworks East has provided innovative design solutions from one of the world’s most flexible, beautiful, and sustainable materials, custom concrete. We have worked on a variety of projects, including the American Airlines headquarters, bars, restaurants, commercial structures, hardscapes, multi-unit residential structures, parks, and city projects. Please contact us today to learn how we can help you.