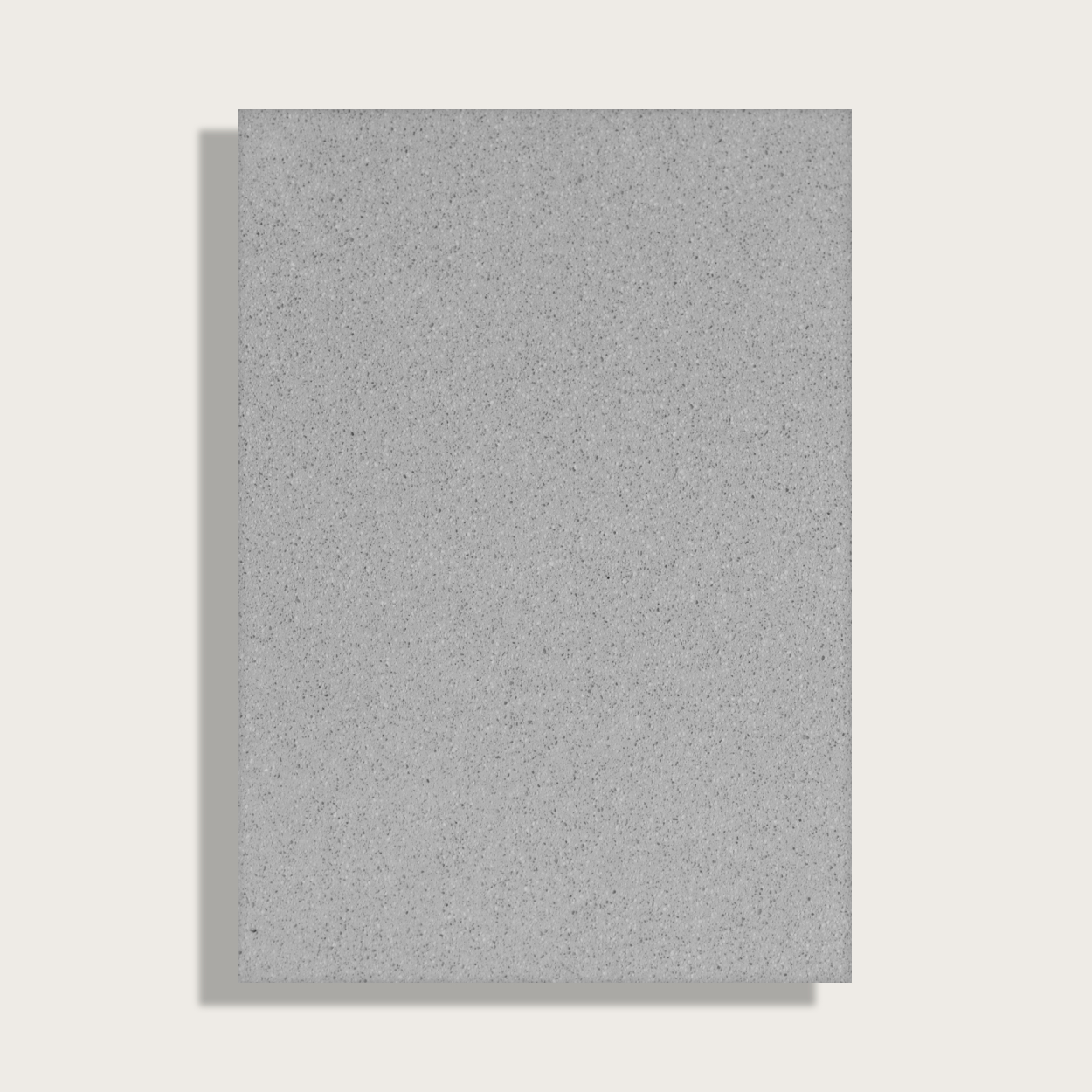

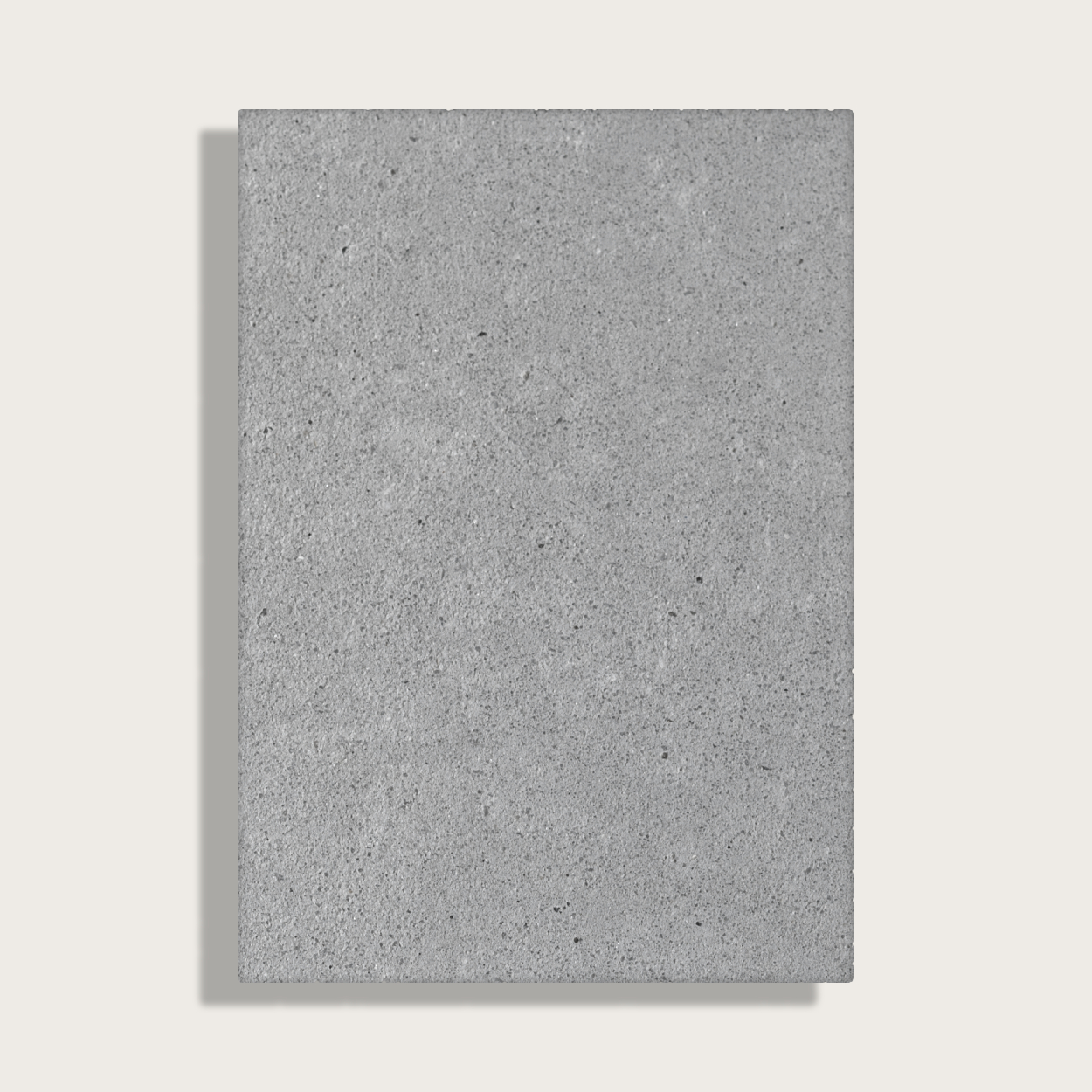

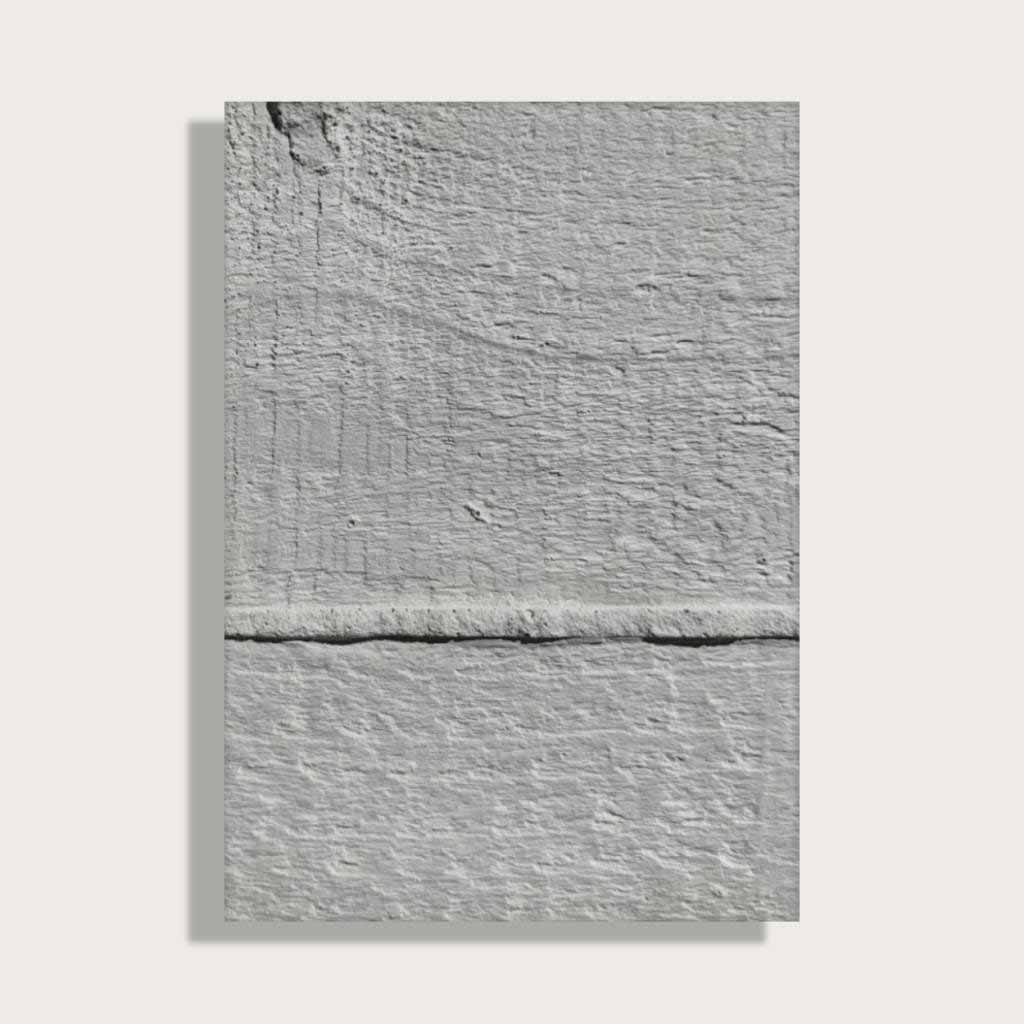

GFRC Wall Panels

Our concrete wall panels are cast using a Glass Fiber Reinforced Concrete (GFRC) matrix, a high performance concrete that allows the panels to be made lighter, stronger, thinner and larger then conventional concrete. Our GFRC wall panels are typically made at 3/4″ – 1″ thick. Since there are no stone aggregates or metal reinforcing within a standard wall panel, GFRC can be cut as easily as natural stone tile allowing you to order one generic size for efficiency or still design each wall panel to a custom size. With a custom concrete wall panel, designers do not need to be constrained by the limited size, shape, and color options of off the shelf or standardized products. Suitable for both exterior and interior uses, GFRC wall panels act as a functional and aesthetic surface that will always last.

Interior Concrete Wall Panels

Whether for a building lobby, and office conference room, or a living room feature wall, custom concrete wall panels will transform any interior space. At Concreteworks East we offer 12 standard colors and a large range of surface finishes, though the possibilities are endless with our custom color development. Our interior wall concrete panels are typically 3/4″ – 1″ thick and can be installed with simply a high strength epoxy adhesive.

Exterior Concrete Cladding

Define the exterior facades of your building with custom GFRC concrete cladding. Our precast panels are available in a custom thickness, typically with a 1″ minimum, that allow for KEIL undercut anchors to be drilled at our facility or on-site. With the undercut anchors in place, the cladding panels can be attached to the building using a Monarch rain screen system. Contact us for more information on installing our concrete panels as exterior cladding.

How Does Precast Concrete Panels Work?

Custom concrete wall panels offer an excellent solution for creating unique and innovative designs in commercial construction projects. Through the use of these panels, architects and designers can achieve beautiful and distinctive facades that enhance the overall aesthetic appeal of a building. These panels are factory-made and cured under controlled conditions, ensuring high-quality and uniformity. The precast panels offer a time-efficient and cost-effective solution for construction projects, as they can be easily transported and installed on-site.

Advantages for Engineers and Architects

Precast panels offer a multitude of advantages for engineers and architects, making them an ideal choice for various construction projects. One of the primary benefits is their superior tensile strength. Precast panels are made by pouring concrete into molds, allowing for a higher tensile strength than traditional poured-in-place concrete. This means that precast panels can withstand greater loads and stresses, providing greater structural stability.

Additionally, precast panels are highly durable. Their manufacturing process involves tightly controlled conditions in a factory setting, resulting in a high-quality product that is resistant to wear and tear. Precast panels can withstand harsh weather conditions, seismic activities, and other external factors, making them a long-lasting solution for buildings.

Versatility is another advantage that precast panels offer. They can be customized to meet various design requirements, including different shapes, sizes, and architectural details. This flexibility in design allows architects to create unique structures that stand out aesthetically.

Uses of Precast Concrete Panels

Precast panels have a wide range of uses, including as exterior wall panels, façades, and structural members. As exterior wall panels, precast panels offer exceptional durability and weather resistance. They can be installed quickly, resulting in reduced construction time and cost. Additionally, precast panels can be easily customized to fit the desired aesthetics of a building.

One of the key advantages of precast panels is their ability to mimic different materials. They can be finished to resemble stone, brick, or stucco, providing the appearance of a high-end, traditional building material without the associated costs and maintenance requirements. This makes precast panels an ideal choice for both residential and commercial buildings.

Moreover, precast panels can be integrally colored, offering a vast array of design options. The ability to incorporate color directly into the panels eliminates the need for additional exterior finishes, reducing overall construction time and costs.

In terms of applications, precast panels are commonly used as façades to add aesthetic appeal to buildings while providing structural support. They have also gained popularity as exterior wall panels in various construction projects due to their durability, versatility, and ease of installation.

Bring Your Vision to Life Today

Are you ready to transform your space with our premium custom concrete wall panels in NY, Boston, MA, and Washington, DC, and all across the US? Contact Concreteworks East today to learn more about our products and services or to schedule a consultation with one of our experts. Let us help you bring your vision to life!

Custom Concrete Wall Panels FAQs

Custom concrete wall panels are typically made with a combination of cement, aggregates, and additives. These materials ensure strength, durability, and performance in the panels.

Custom concrete wall panels offer a wide range of customization options. These panels can be made in various sizes, shapes, and patterns to fit the unique requirements of any project. Additionally, they can be custom-colored to achieve a desired aesthetic.

Custom concrete wall panels are highly durable. They are engineered to withstand harsh weather conditions, impacts, and wear over time. The materials used ensure strength and longevity, making them suitable for both indoor and outdoor applications.

Custom concrete wall panels can be customized to match any color palette. They can be pigmented to a specific color or stained to achieve a natural aesthetic. This allows for endless design possibilities and ensures seamless integration with any interior or exterior design scheme.